72" x 30' 1305 PSI Sour Horizontal Separator Vessel w/ water boot - 16015

72" x 30' 1305 PSI Sour Horizontal Separator Vessel w/ water boot - 16015

Location:Redcliff Yard

Description

Scope

To supply one 72” x 30’ 600 ANSI 1305 PSI 3-phase Separator Package (fully refurbished), pricing is inclusive of material supply, fabrication, inspection, testing for all new packaging. Pricing and exceptions contained herein. Externals

· (1) Standard Set of Saddles (SA36/44W, 8" W, 3/8", ~72” H)

· (1) Bridle (A106B, 4” NPS STD, 2” connections)

· (1) Water Boot (SA516-70N, 1” T)

Skid

· 10’ W x 37’-6” Flat Skid

· 12" @ 45#/ft Wide Flange main members

· 6” @ 10.5#/ft Channel cross members

· 1/4” Checker Plate floor

· (6) Lifting lugs

Fabricated to CWB specifications

Building

· (1) 10’ W x 17’-6” L x 14’ low eave, 4:12 gable style self-framing enclosure.

· 22-gauge ASTM A653/A792 Gr.37, Galvalume. Roof, doors, exhaust hoods and trim warm grey.

· 24-gauge white fluted aluminum c/w R-12 wall insulation and R-20 roof insulation c/w 6 mil vapor barrier.

· (1) 3’ x 7’ steel single door 20-gauge PU c/w IWG, 16-gauge door frame, Von Duprin 44TP panic, check chain, weather-strip, aluminum threshold and canopy.

· (2) 12” x12” manually adjustable louvers c/w screen.

· (2) 24” x 24” Natural Gas Heater, 12 Volt, 7” WC c/w snap on grill, AC-R-289, AC-TC-8000N-7, and 25’ cable.

· Caulking, patches and screws.

· (1) Full length ice rakes and eavestroughs c/w (2) downspouts.

Note: Building size and building heater are subject to detailed layout. Cost changes may apply.

Piping

· Gas Inlet - 6” ANSI 600# RF – Blinded vessel connection (piping by others).

· Gas Outlet – 6” ANSI 600# RF flanged welded pipe, Sch 80, to meter run, then skid edge.

· Water Outlet - 2” ANSI 600# RF flanged welded pipe, Sch 160, to skid edge.

· HC Outlet – 2” ANSI 600# RF flanged welded pipe, Sch 160, increased to 3” ANSE 600# flange welded pipe, Sch 80, to skid edge.

· Drain – 2” ANSI 600# RF flanged welded pipe, Sch 160, to skid edge and tie to Water Line.

· Relief Piping – 3” ANSI 600# RF flanged nozzle, Sch 160, reduced to 2” ANSI 600# RF flanged welded pipe, Sch 160 to relief valve (2” 600# x 3” 150#), 3” ANSI 600# RF flanged welded pipe, Sch 80, increases to 4” ANSI 600# RF flanged welded pipe, Sch 80, to skid edge.

· Instrument Air In – 1/2” 3000# Skid edge connection to regulators

· All connections exiting building to be of “low temp” material up to first fitting inside building unless otherwise noted.

Materials of Construction

Threaded Pipe: SA-106B/SA-333 Gr 6 Sch. 80/160

Threaded Fittings: SA-105N/SA-350 LF2 C1, 3000#

Welded Pipe: SA-106B/SA-333 Gr 6 Sch. 40 / STD / 80 / XH

Flanges: SA-105N/SA-350 LF2 C1 300#/600#

Weld Fittings: SA-234 WPB/SA-420 WPL6

Threadolets / Weldolets: SA-105N/SA-350 LF2 C1

Gaskets: 1/8-inch, GASKETS FLEX CGI ASME B16.2 316L

Bolting: SA-193-B7M/SA-194-2HM

Testing

· Sour Service c/w 100% Radiography

· Sweet Service c/w 10% Radiography

· Hydrostatic Testing, 1.5x Full Flange ANSI Rating.

· Fabricated to ASME B31.3 NFS.

· Any additional testing or requirements not listed here that is requested by customer or customer specifications will be at extra cost.

Note: Piping is subject to a detailed layout. Cost changes may apply.

Painting & Coating

Vessel and Bridle

Internal Blast: nil

Internal Coating: nil

External Blast: SSPC-SP3

External Primer: 1.5 – 2.0 mils DFT Cloverdale Alkyd Primer

Paint: 1.5 – 2.0 mils DFT Cloverdale Alkyd Marine Enamel

Color: Warm Grey

Piping

Internal Blast: nil

Internal Coating: nil

External Blast: SSPC-SP3

External Primer: 1.5 – 2.0 mils DFT Cloverdale Alkyd Primer

Paint: 1.5 – 2.0 mils DFT Cloverdale Alkyd Marine Enamel

Color: Warm Grey

Skid

Blast: SSPC-SP3

Primer: 1.5 – 2.0 mils DFT Cloverdale Alkyd Primer

Paint: 1.5 – 2.0 mils DFT Cloverdale Alkyd Marine Enamel

Color: Warm Grey

Insulation

Vessel

· Insulation is included for 20’ of the exposed vessel shell, and one exposed head.

Skid

· The underside of skid will be insulated with 2” spray urethane.

Piping

· Piping insulation has not been included in the current scope of supply.

Electrical Not Included

Specifications

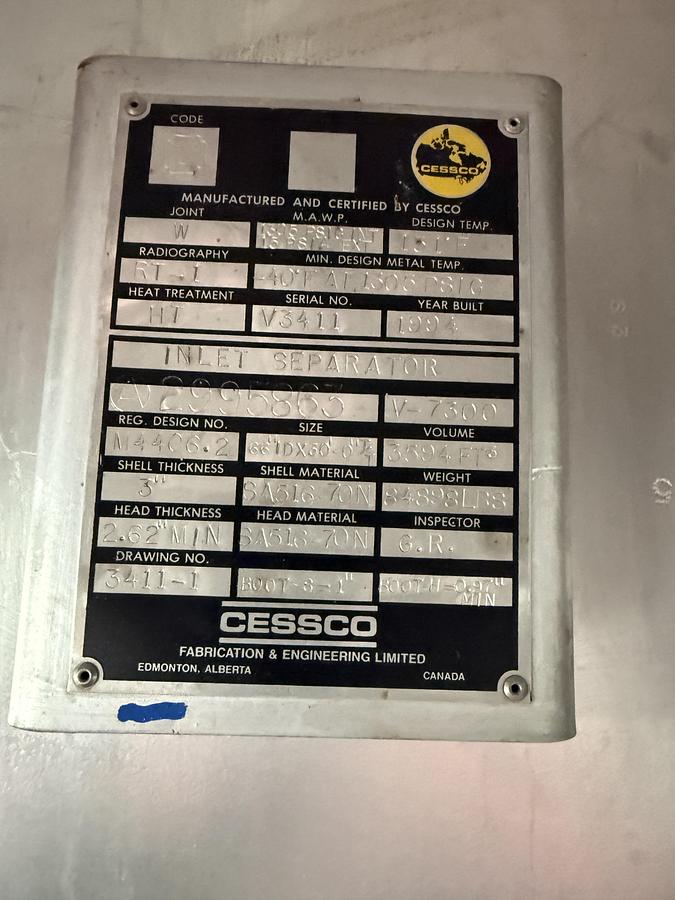

| Manufacturer | Cessco |

| Year | 1994 |

| Condition | Refurbished |

| Serial Number | V3411 |

| Stock Number | 16015 |

| Diameter | 72" |

| Design Pressure | 1305 PSI |

| Orientation | Horizontal |

| Service | Sour |

| Length | 30' |

| Phase | 3 Phase |

| A# | 2995863 |

| CRN# | M4406.2 |

| Inlet | 6" 600 ANSI RF |

| Outlet | 6" 600 ANSI RF |

| Condensate Details | 2" 600 ANSI RF |

| H2O Details | 2" 600 ANSI RF |